<---Previous =============== Next--->

Body Construction

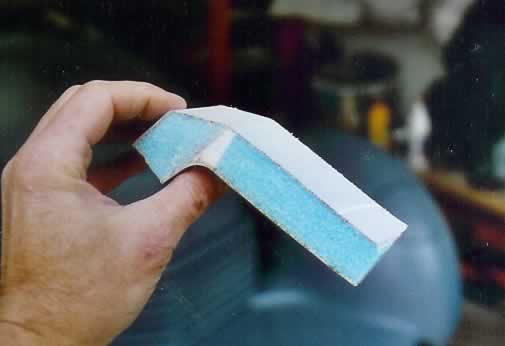

The idea was to make a car body out of light-weight

composite structure made up of a sandwhich of fiberglass/foam/fiberglass.

This construction is used extensively in high performance home-built aircraft,

sail planes and surf boards. The foam is easily formed by sanding.

Once shaped, the outside is fiberglassed. This is done by wetting

sheets of fiberglass with epoxy. Epoxy is strong and gives

you plenty of time to work before setting up. Polyester resin, on

the other hand, cures in 15 to 20 minutes - not much time to work.

Another draw back is that polyester resin disolves styrofoam - not good.

Once the epoxy is cured, the panel is turned over and

all but 3/4 inch of foam is removed. The inside foam surface is

then sanded smooth and covered with hand layed-up fiberglass.

The resulting structure is very strong and rigid. You can easily

stand on the fenders and hood. The next step is to sand the

fiberglass, paint and viola! You're done!

Facets have been added in between the ribs. Left fender sanded.

Note hood and grill have been mocked up to verify geometry. (Nov

1985)

The front and rear fenders are being made. Left and right ribs were

carefully made to ensure symmetry. (Photo taken Oct 1985)

Rear is remade because the original foam did not look right. This

is just the beginning of lots of engineering changes. (Nov 1986)

Facets installed. (Nov 1986)

The outer surfaces have been fiber- glassed. Design changes continue.

The rear of the front fenders are being lowered. (April 1987)

Inside of the front fenders is being prepared for fiberglassing.

(June 1987)

Close up view of composite structure. (Sept 2005)

Me standing on a slender panel of fiberglass/foam/fiberglass. (Nov

88)

Removeable hardtop roof being sculpted from foam. (Dec 88)

The car is rolled out of the garage for the first time. 2X4 serves

as a brake. (June 1989)

<---Previous =============== Next--->

Hosted by MagicWeb.us